DCS & PLC Systems

Learn all about these impressive, and often complex systems.

How do they compare? What features do they offer? We are here to help you understand what solutions are right for you!

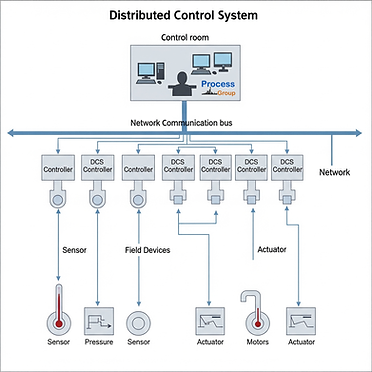

DCS: Distributed Control System

A DCS is computerised control system used in industrial settings to manage and automate complex processes or entire plants. DCS installations are widely used in large-scale, continuous-process industries where reliability and safety are paramount. Examples include:

-

Oil and gas refineries

-

Chemical plants

-

Power generation plants

-

Pulp and paper mills

-

Water and wastewater treatment facilities

Unlike older, centralized systems where a single computer controlled everything, a DCS uses many independent controllers that are geographically spread out across a factory or plant. Each of these controllers manages a specific part of the process, such as a particular machine or area.

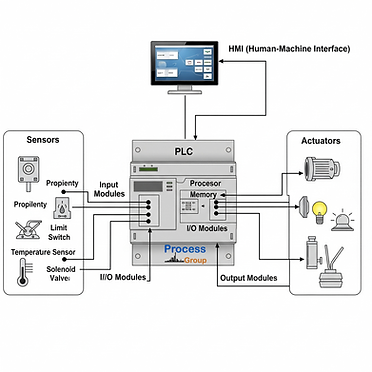

PLC: Programmable Logic Controller

Essentially an industrial computer used to automate manufacturing processes and other control systems. It's designed to withstand harsh environments like those with dust, heat, or moisture, and it offers high reliability and ease of programming. Among many, applications include:

-

Food & beverage production

-

Water & wastewater treatment

-

Automated manufacturing facilities

- Energy & power generation/management

PLCs were originally developed to replace complex, hard-wired relay logic systems, making it simpler and more cost-effective to modify or update control processes. They are an example of a hard real-time system, meaning they must produce an output in response to an input within a very specific and limited timeframe to prevent unintended operations.

What's the difference?

DCS is ideal for process-oriented industries with complex control needs.

PLC shines in machine-oriented applications requiring speed and precision.

The Process Group Approach

Regardless of which system fits your requirements, we can design, implement, troubleshoot, upgrade and maintain any DCS or PLC system you're running. We can advise on obsolescence and perform risk assessments on existing equipment. this ensures you are fully aware of potential breakdown risks to help you avoid costly unplanned shutdowns.

Lets talk about reducing your downtime.

info@process-group.co.uk

+44 (0) 1642 438 190

Chat Now (Mon-Fri 08:00 - 16:00 UK Time)